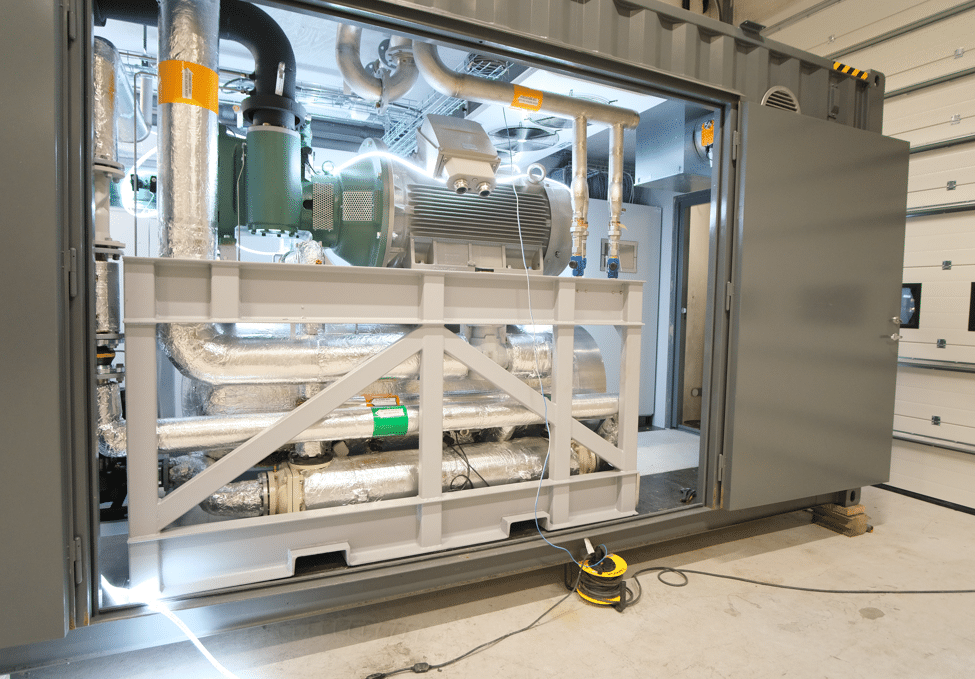

Øen Kuldeteknikk has now delivered 3 40-foot prefabricated refrigerated containers from our workshop in Hornindal to Statkraft and Oslo Airport City.

The facility is now being completed with the installation of dry coolers, pipes and cabling. Commissioning and a test period also follow before handing over to the customer.

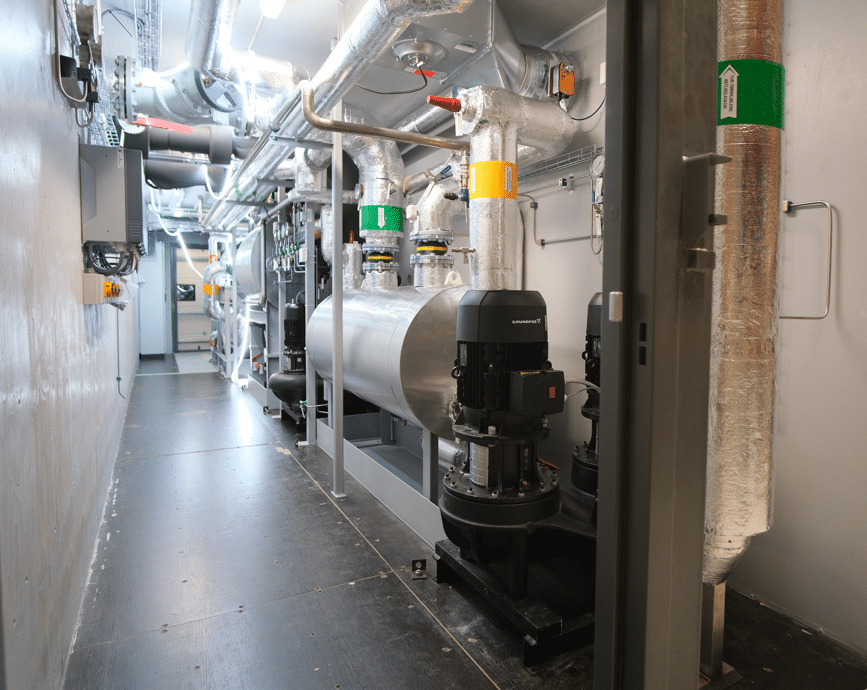

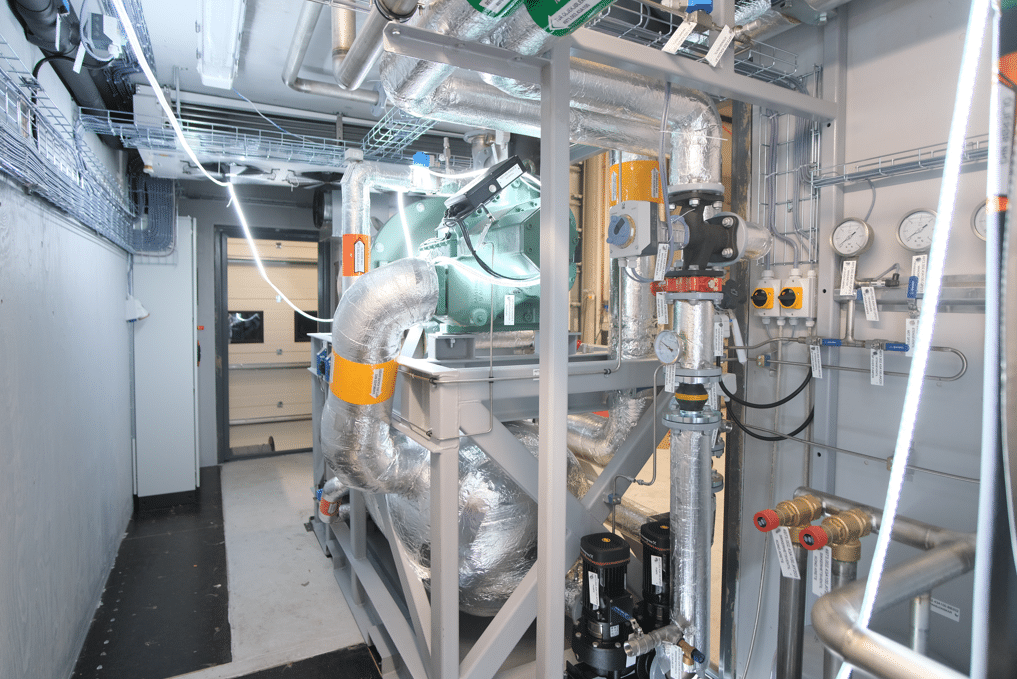

Containers 1 and 2 are identical and contain the cooling machines themselves.

Main components used:

- Bitzer Ammonia compressor with 1040kW cooling power.

- Siemens Electric motor.

- Vacon frequency converter.

- Bitzer oil separator.

- HS-Cooler oil cooler.

- Vahterus evaporates.

- Vahterus condenser.

- Grundfos circulation pumps.

- LUVE dry coolers.

- Owned Elektro dashboard.

- Caverion automation and control system.

- LøFlo Elektro installation.

Container 3 contains equipment for the district cooling system itself.

Main components used:

- Grundfos circulation pumps.

- Vacon frequency converters.

- Clear Water water purification system.

- Clear Water vacuum aerator.

- Owned Elektro main board.

- ABB Freelance automation and control system.

- LøFlo Elektro installation.

We take this opportunity to thank Statkraft, Norsk Energi and Multiconsult for their cooperation.